AUTOMATIC AUGER FILLER

General description

This type can do dosing and filling work. Dosing by auger or by load cell are at options. Due to the special professional design, it is suitable to the fluidic or low-fluidity materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder, agriculture pesticide, dyestuff, and so on.

Main features

- 304 Stainless steel construction

- All material contact welds ground smooth, electropolish interior

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Quick disconnecting hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Adjustable height turret, -Turret can swing 180° to each side

- Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

Designs

Specifications

| Model | TP-PF-A10 | TP-PF-A21 | TP-PF-A22 |

| Control system | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | 11L | 25L | 50L |

| Packing Weight | 1-50g | 1 – 500g | 10 – 5000g |

| Weight dosing | By auger | By auger | By auger |

| Packing Accuracy | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 – 500g, | ≤ 100g, ≤±2%; 100 – 500g, |

| ≤±1% | ≤±1%; ≥500g,≤±0.5% | ||

| Filling Speed | 40 – 120 times per min | 40 – 120 times per min | 40 – 120 times per min |

| Power Supply | 3P AC208-415V | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| 50/60Hz | |||

| Total Power | 0.84 KW | 1.2 KW | 1.6 KW |

| Total Weight | 90kg | 160kg | 300kg |

| Overall | 590×560×1070mm | ||

| Dimensions | 1500×760×1850mm | 2000×970×2300mm |

Machine advantage

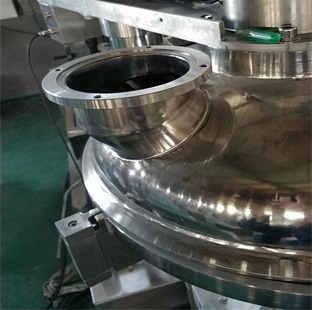

- Arc design, no material stock, easy to clean

- 1.5mm thickness stainless steel

- P+F brand, it is more suitable for all kinds of materials, especially dusty materials.

- Feed inlet —feed inlet with radian to reduce impact for hopper.

- Air outlet with quick connection type, more convenient installation and dis-assembly.

- Side-open hopper

Easy to open and clean.

- Different sizes metering auger and filling nozzles—-to metering different filling weight and suitable for container mouth with different diameter.

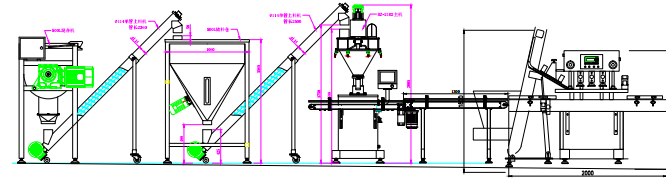

Production line

screw feeder→ribbon mixer→screw feeder→automatic auger filler → automatic capping machine-> labeling machine-> coding machine….

Auger Filler Automatic machine + Screw Conveyor + Screw Feeder + Ribbon Blender

Auger Filler Automatic machine + Screw Conveyor + Screw Feeder + Ribbon Blender