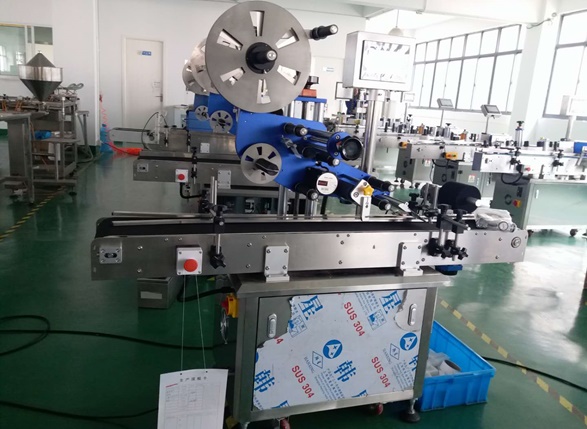

LABELING MACHINE

General introduction

Use: Achieve automatic labeling the adhesive label or adhesive film on flat surface or large radical surface of the products.

Label applicable: adhesive labels; adhesive films; electronic supervision code, bar code etc.

Product Applicable: The products which must be labeled with paper label or film label on top side,bottom obliquity,roughness side or flat surface of paper box,case box,bottle cap,cup,cosmetic box,square/flat bottle,electrical components,battery etc.

Product advantage

- Effect: improve labeling efficiency, accuracy and quality and stability; Avoid many problems such as low efficiency of labor labeling, skew labeling, bubble, wrinkle, irregular labeling etc; Lower product cost effectively and make the product more beautiful which lead the product to be more competitive.

- Adopt standard PLC + touch screen + stepper motor + standard sensor electric control system. High safety coefficient; Complete English writing human-machine interface; has advanced fault remind function and operation teaching function; convenient to use and easy to maintain.

- The clever design which allow user to mechanically adjust some structure combination and label winding, makes it easy to adjust the labeling position freely (it can be fixed easily after adjustment). All these make the change of different products and winding of labels more simple and saving time.

- Has the automatic detecting function to stop labeling if there is no bottle and automatic correcting function if there is no label. It solves the miss labeling problem caused by label roll.

- Has fault alarm function, production counting function, energy saving function (the machine will be on standby mode when there is no label pass in the certain time), and production amount remind function; Parameter-set protection function.

Technical parameter

| Labeling precision | ±1mm (exclude the product and label deviation) |

| Labeling speed | 600-1200BPH (related to product size) |

| Product size applicable | 15≤width≤200mm, length≥10mm |

| Label size applicable | 15≤width≤130mm, length≥10mm |

| Size of whole machine | 1600×800×1400mm (length×width×height) |

| Power supply | 110/220V 50/60HZ |

| Weight | 180kg |

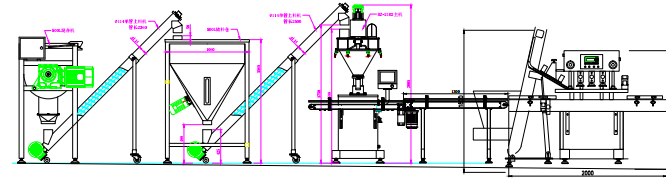

Production line

screw feeder→ribbon mixer→screw feeder→automatic auger filler → automatic capping machine-> labeling machine-> coding machine….