CAPPING MACHINE

General description

TP-TGXG-200 Bottle Capping Machine is an automatic capping machine to press and screw lids on bottles. It’s special designed for automatic packing line. Different to traditional intermittent type capping machine, this machine is a continous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm the lids. Now it’s widely applied in food, pharmaceutical, chemical industries.

It consists of two parts: capping part and lid feeding part.

It works as following: Bottles coming (can joint with auto packing line) → Convey→ Separate bottles in same distance→ Lift lids→ Put on lids→ Screw and press lids→ Collect bottles.

Characteristics

- PLC&touch screen control, easy to operate.

- Speed of conveying belt is adjustable to synchronous with whole system.

- Stepped lifting device to feed in lids automatically.

- Lid falling part can remove error lids away(by air blowing and weight measuring).

- All the contact parts with bottle and lids are made of material safety for food.

- The belt to press the lids is inclined, so it can adjust the lid into the correct place and then pressing.

- Machine body is made of SUS 304, meet GMP standard.

- OPTION: Optronic sensor to remove the bottles which are error cappe.

- OPTION: Digital display screen to show the size of different bottle, which will be convenient for changing bottle.

Parameters

| Capacity | 50-100 bottles/min |

| Dimension | 2100*900*1800mm |

| Bottles size | Φ22-120mm (customized) |

| Bottle height | 60-280mm (customized ) |

| lid size | Φ15-120mm (customized) |

| Weight | 350kg |

| Lid size | Φ15-120mm |

| Power | 1300W |

| Qualified rate | ≥99% |

| Voltage | 220V/50-60Hz(or customized) |

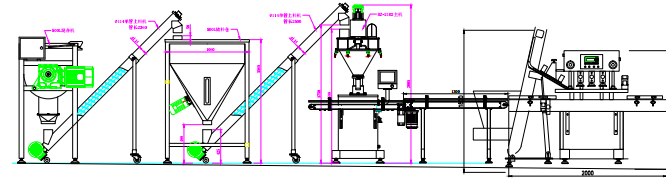

Production line

screw feeder→ribbon mixer→screw feeder→automatic auger filler → automatic capping machine-> labeling machine-> coding machine….